Fuel transfer pumps are essential in various industries, from agriculture to automotive and industrial sectors. These pumps make transferring fuel from one location to another easier, safer, and more efficient. Whether you need to refuel heavy machinery, transport fuel for your farm equipment, or move fuel for emergencies, a fuel transfer pump ensures a smooth and reliable process. This article will explore everything you need to know about fuel transfer pumps, including their working mechanism, types, applications, and how to choose the right one for your needs.

What is a Fuel Transfer Pump?

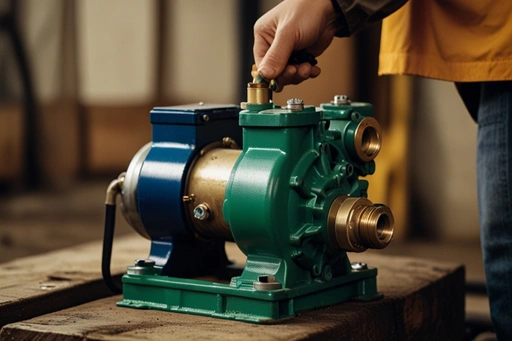

Fuel is moved from one container to another by a fuel transfer pump. It typically consists of a pump mechanism, hoses, and various fittings to connect the pump to fuel tanks or other storage containers. These pumps are used in multiple industries, including automotive, construction, agriculture, and marine operations. Whether you’re transferring gasoline, diesel, or oil, a fuel transfer pump ensures the safe and efficient movement of fuel, minimizing waste and reducing the risk of spills.

Why is a Fuel Transfer Pump Important?

The importance of a fuel transfer pump cannot be overstated. Industries that rely heavily on fuel-powered equipment need a reliable and efficient way to transfer fuel. Manual fuel transfer methods are time-consuming and increase the risk of fuel spillage and environmental harm. A fuel transfer pump helps mitigate these risks by offering a controlled and easy way to transfer fuel, reducing accidents and improving workplace safety.

How Does a Fuel Transfer Pump Work?

A fuel transfer pump creates a pressure difference that allows the fuel to move from one location to another. The pump typically uses a manual or electric motor to power the mechanism. When you activate the pump, the motor draws fuel into the pump mechanism, and a hose connected to the pump directs the fuel into the desired storage tank or container. Electric models are faster and more convenient, while manual pumps are ideal for small-scale operations and portable use. Regardless of the model, a fuel transfer-pump makes the fuel transfer process easier and more effective.

Types of Fuel Transfer Pumps

Several types of fuel transfer pumps are suited for different applications. The most common types include:

Manual Fuel Transfer Pump: These pumps require physical effort to operate. They are often used in small-scale operations where electricity is not available or practical. Manual pumps are affordable and portable, making them ideal for personal use or small businesses.

Electric Fuel Transfer Pump: Electric fuel transfer-pumps are more powerful and efficient than manual pumps. They can transfer fuel quickly and with minimal effort. These pumps are commonly used in commercial and industrial settings where high fuel volumes must be moved frequently.

Pneumatic Fuel Transfer Pump: Pneumatic pumps use compressed air to drive the fuel transfer process. They are commonly used in heavy-duty industrial applications, where ample fuel must be moved quickly.

Hand-Operated Fuel Transfer Pump: These pumps are specifically designed for small-scale operations. Hand-operated models are ideal for transferring fuel in portable or emergencies where electricity or air pressure is unavailable.

Each type of fuel transfer-pump has advantages and disadvantages. Understanding your specific p, you choose the right one for your applications.

Applications of Fuel Transfer Pumps

Fuel transfer pumps are used in a variety of industries and settings.Many industries rely on fuel transfer pumps for a variety of essential tasks, such as:

Automotive Industry: Car repair shops, service stations, and emergency vehicles use fuel transfer-pumps to move fuel from storage tanks to vehicles. These pumps are essential for ensuring fuel is readily available for refueling operations.

Agriculture: Farmers use fuel transfer pumps to refuel their machinery and equipment, including tractors, harvesters, and irrigation pumps. These pumps help keep agricultural operations running smoothly by ensuring fuel is available for large machinery.

Marine: Fuel transfer pumps refuel boats and ships at docks or during long voyages. A reliable transfer pump is crucial to ensure continuous operation since large amounts of fuel are needed to power marine engines.

Construction and Heavy Equipment: In construction, fuel transfer-pumps refuel bulldozers, cranes, and other large machines. These pumps ensure fuel is delivered quickly and efficiently to heavy equipment on-site, minimizing downtime and keeping projects on schedule.

Emergency Services: Fuel transfer-pumps transport fuel quickly and safely to generators, firefighting equipment, and other emergency tools during emergencies. They are critical for maintaining operations during power outages or disaster recovery.

Benefits of Using a Fuel Transfer Pump

Using a fuel transfer pump offers several advantages over traditional methods of fuel handling. Some of the key benefits include:

Efficiency: A fuel transfer-pump speeds up the process, allowing you to move fuel more quickly and efficiently. Whether refueling large machinery or transferring fuel to storage containers, a pump ensures the process is done faster than manual methods.

Safety: Fuel transfer pumps are designed to reduce the risk of spills and accidents. Using a pump can better control fuel flow, preventing overflows and minimizing the environmental impact of any potential spills.

Convenience: A fuel transfer pump eliminates the need for manual labor to move fuel, saving time and reducing the physical strain of fueling large equipment or vehicles.

Cost-Effectiveness: While purchasing a fuel transfer pump may require an initial investment, it saves money in the long run by reducing fuel waste, improving fuel efficiency, and minimizing the risk of accidents and equipment damage

Tips for Selecting the Best Fuel Transfer Pump

When selecting a fuel transfer pump, you must consider several factors to ensure you choose the right one for your needs. These factors include:

Type of Fuel: Not all pumps are suitable for every fuel type. Some fuel transfer pumps are designed for gasoline, while others are intended for diesel, oil, or other fuels. Make sure the pump you choose is compatible with the type of fuel you plan to use.

Flow Rate: The pump’s flow rate determines how quickly it can transfer fuel. If you need to move large amounts of fuel quickly, choose a pump with a high flow rate. However, a lower flow rate pump will suffice if you only need to transfer small amounts of fuel.

Portability: Depending on your application, you may need a portable pump that can quickly move from one location to another. Manual pumps are typically more portable, while electric pumps may be bulkier but offer more power.

Power Source: Fuel transfer pumps can be powered by electricity, manual effort, or compressed air. Consider which power source is most practical for your setup, primarily if you work in remote locations where electricity is unavailable.

Durability: Since fuel transfer pumps are often used in harsh environments, choosing a pump made from durable materials is essential to ensure long-lasting performance. Look for pumps with high-quality seals, corrosion-resistant materials, and solid construction.

Conclusion

A fuel transfer pump is a valuable tool for many industries; It provides a safe, efficient, and cost-effective way to transfer fuel. Whether you need to refuel machinery, transport fuel for emergencies, or handle fuel in industrial applications, a fuel transfer pump is an indispensable asset.

Understanding the different types of pumps, their applications, and how to choose the right one for your needs can ensure that your fuel transfer operations are always smooth and efficient. Choose the proper fuel transfer pump today to enhance your productivity and safety in fuel handling.